Manufacturers are constantly seeking ways to increase profitability, whether through cost-cutting or the implementation of modern technologies.

One customer asked R.E. Mason to review a control valve rebuild task that occurred each outage. Our control valve expertise, combined with diagnostics technology, enabled this customer to implement reliability improvements and reduce repetitive costs.

One customer asked R.E. Mason to review a control valve rebuild task that occurred each outage. Our control valve expertise, combined with diagnostics technology, enabled this customer to implement reliability improvements and reduce repetitive costs.

Identifying and Understanding the Root Cause

R.E. Mason’s Mechanical & Valves Services team, , in collaboration with the customer, pinpointed the design of the Power Boiler Feedwater Control Valve as a cost savings opportunity. The mill replaced the entire feedwater control valve trim (cage, plug, and seat ring) every two years. Historical repair reports described significant trim damage, making the trim beyond repair and causing costly replacements.

Further investigation with the customer’s operations team revealed that the feedwater process control loops experienced high variability and a lack of control to the desired setpoint. R.E. Mason’s engineering team, in partnership with Emerson’s Fisher factory team, found a misalignment between the valve characterization and the process conditions that caused excessive loop instability

Further investigation with the customer’s operations team revealed that the feedwater process control loops experienced high variability and a lack of control to the desired setpoint. R.E. Mason’s engineering team, in partnership with Emerson’s Fisher factory team, found a misalignment between the valve characterization and the process conditions that caused excessive loop instability

Control Valve Retrofit with Characterized Trim versus Replacement

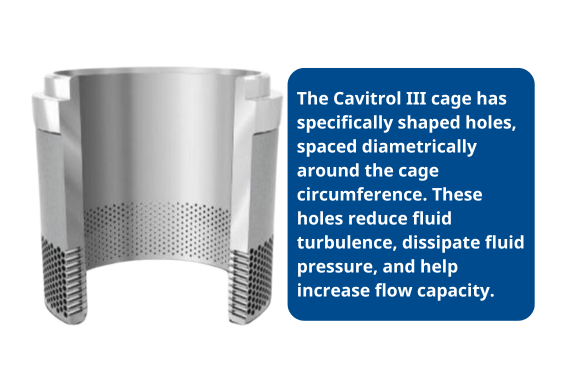

R.E. Mason and Emerson engineered a characterized cage design with the proper process control range to retrofit the existing valve. This eliminated the need to replace the entire valve assembly at a six-figure cost.

Predictive Health Strategies using Valve Diagnostics

We worked with the mill operations and maintenance teams to leverage condition monitoring diagnostics available in the FIELDVUE DVC6200. for condition monitoring to help predict when maintenance might be required. This enables them to predict when maintenance is required, heading off costly repairs.

Delivering Results

Improved runtime experience and a comfort level with condition monitoring convinced mill management to extend the maintenance interval from two to six years. Aggressive loop tuning improved process control during large demand swings, preventing boiler trips and relief valve venting.